Precision manufacturing innovation

We are a technology-driven global precision manufacturing partner.Innovation-driven in the precision manufacturing field has been our company's mission.

High accuracy and reliability

Reliable and stable precision metal and plastic parts R&D and manufacturing,surface treatment technology application and innovation. We have produced more than 20 million precision stamping and plastic parts which are used in high-end European automotive brands.

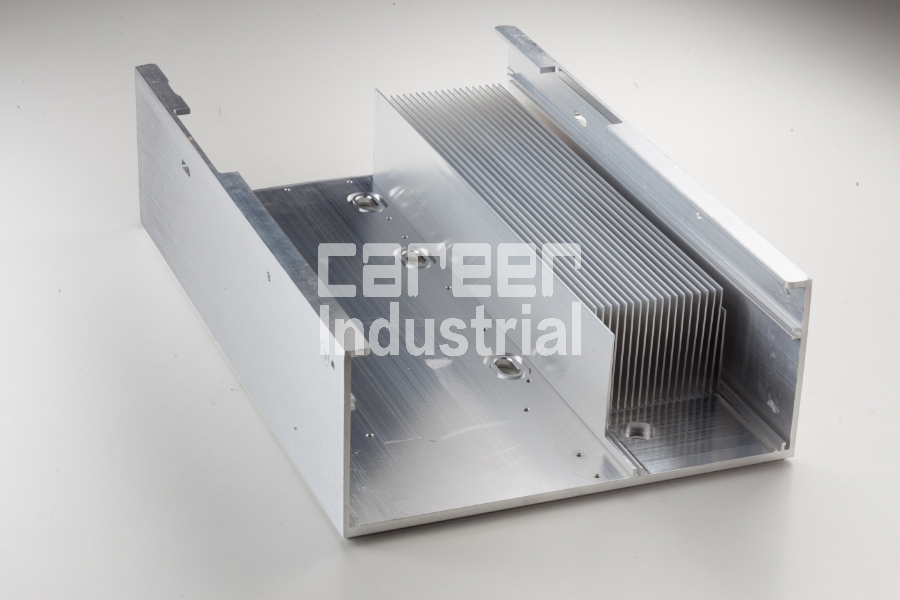

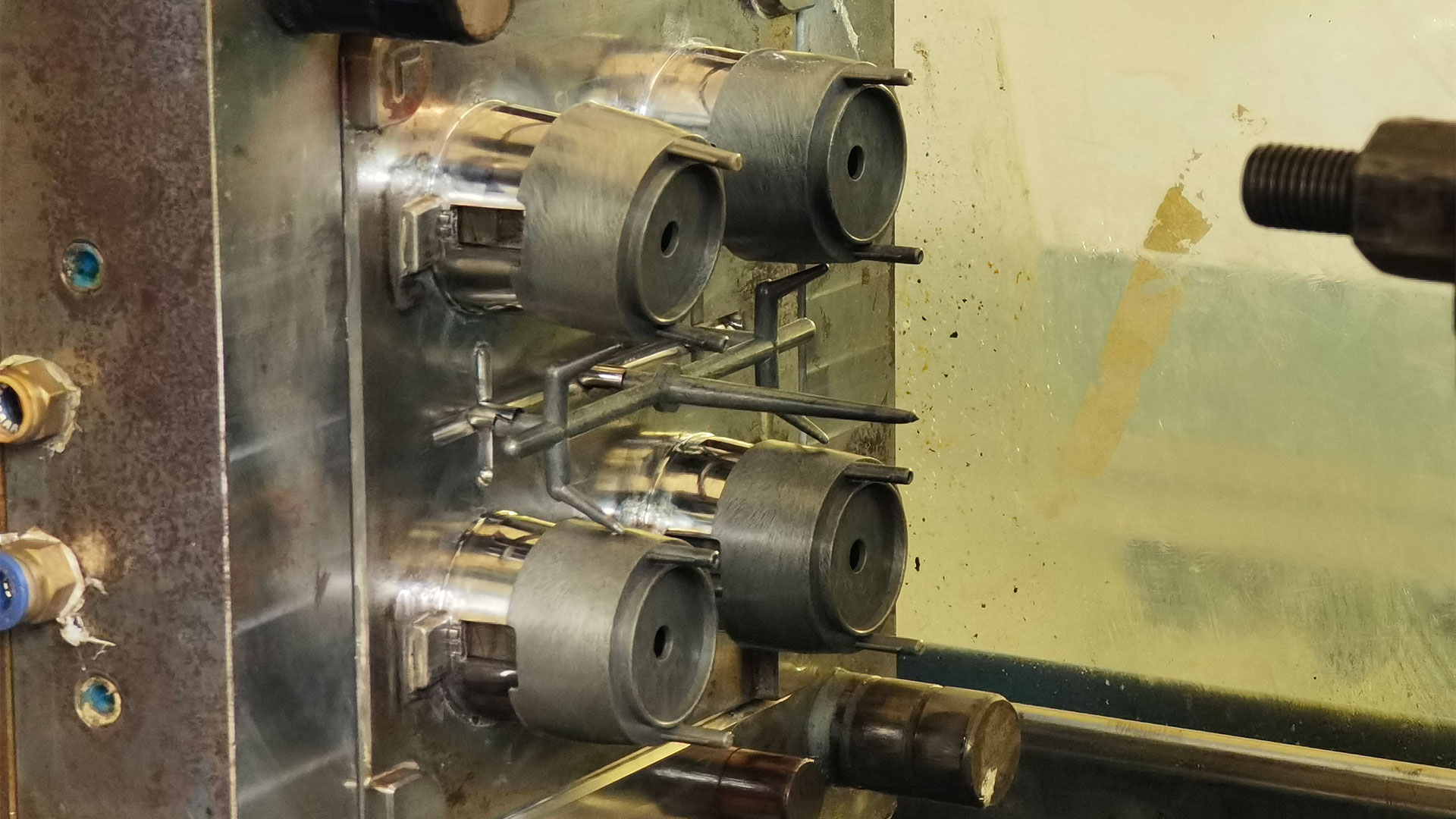

Precision large-scale deep drawing

We have 600T -800T large stretching equipment, width of stretching size is 600MM. The length is 1500MM and the height is 300MM. Applying to the solar energy storage inverter, water pump, heater deep drawing shell.

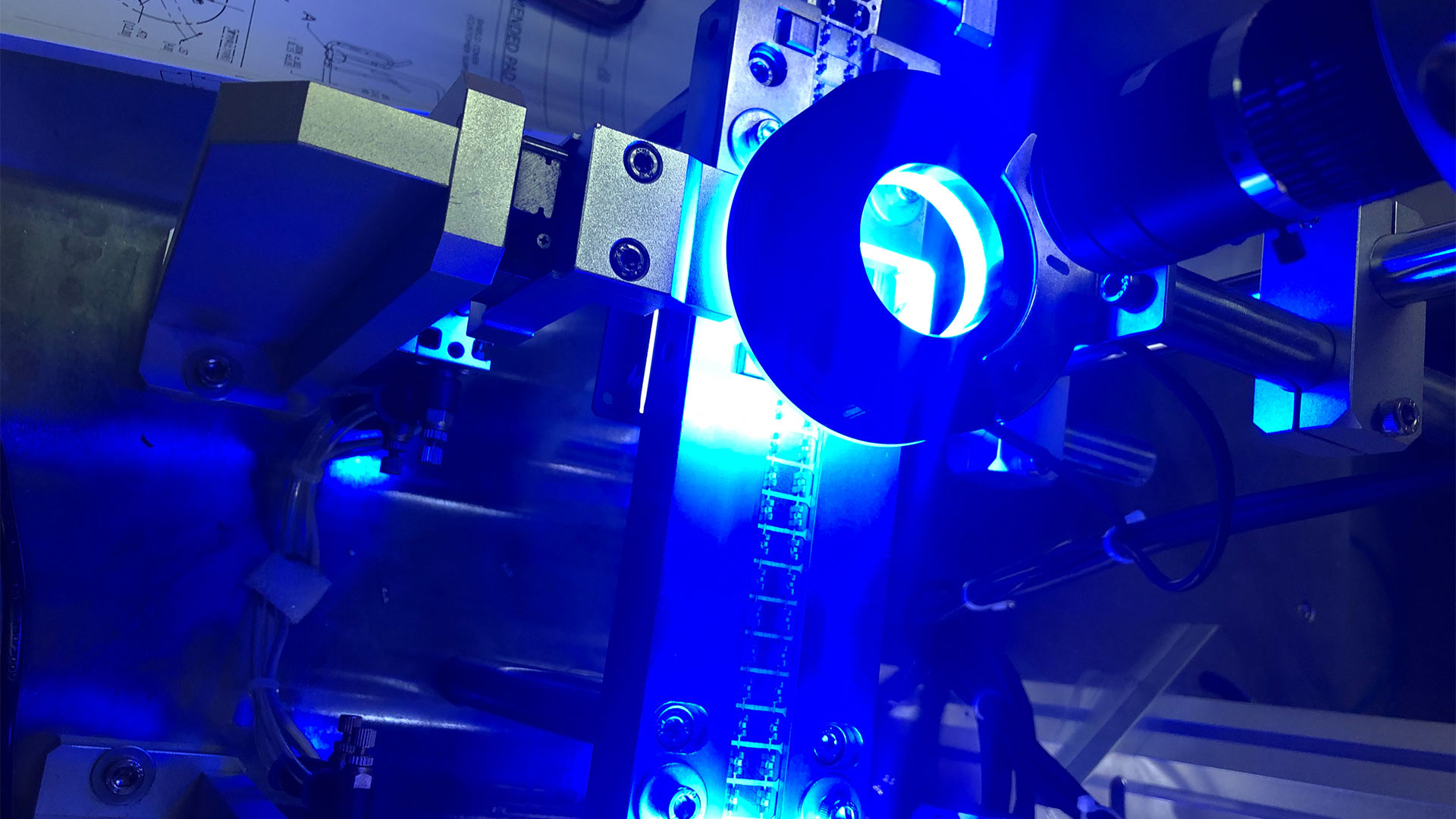

Integrated automated CCD inspection

For the precision and complex parts, we will use the most advanced CCD testing equipment to ensure that the parts’ core size will not be deformed during the precision stamping, it is a very important process in the field of medical equipment and auto parts.

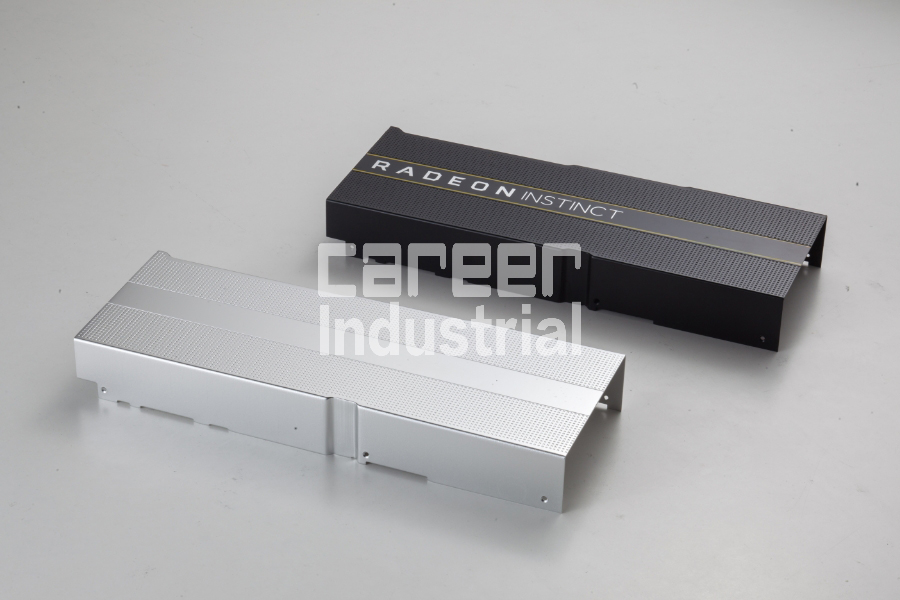

One-stop service for surface treatment

Focus on high standards, high quality precision metal stamping, plastic injection surface treatment and application innovation, powder coating, painting, electroplating, color electrophoresis, passivation, laser engraving, printing, wiredrawing, polishing, electrolytic oxidation, hard oxidation, oxidation, heat treatment, passivation, UV, PVD, IML, IMD and so on.

Quality Assurance

We have different kinds of precision testing equipment and perfect quality system :TUV IATF16949:2016, NQA ISO13485:2016, AS9100, Nadscap. For example: CMM, image measuring instrument, height ruler, micrometer, film thickness instrument, colorimeter, salt spray tester, push /torque test machine and so on

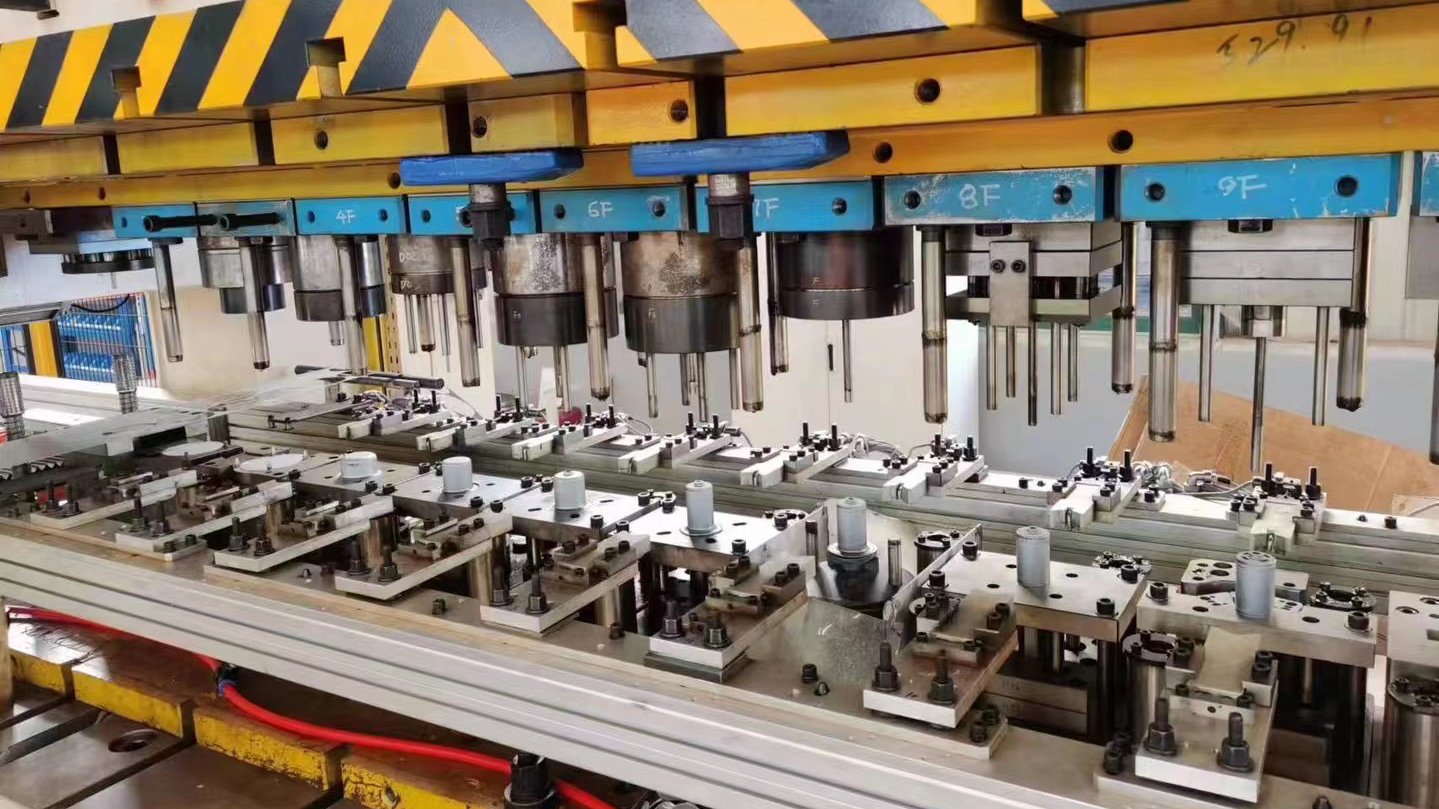

Precision metal stamping

We have 20 sets of precision stamping equipment from 60T to 300T ,single and double axis, focus on precision fine blanking, large-scale deep drawing, progressive stamping. Raw material thickness is from 1.0MM to 10MM

Precision plastic injection

We have more than 20 sets of precision plastic injection equipment, including vertical injection machine, horizontal injection mechane, our technical advantage is to provide customers with a variety of color molding, metal & plastic injection coating, These products are mainly used in automotive, medical equipment, new energy, medical equipment and other fields.

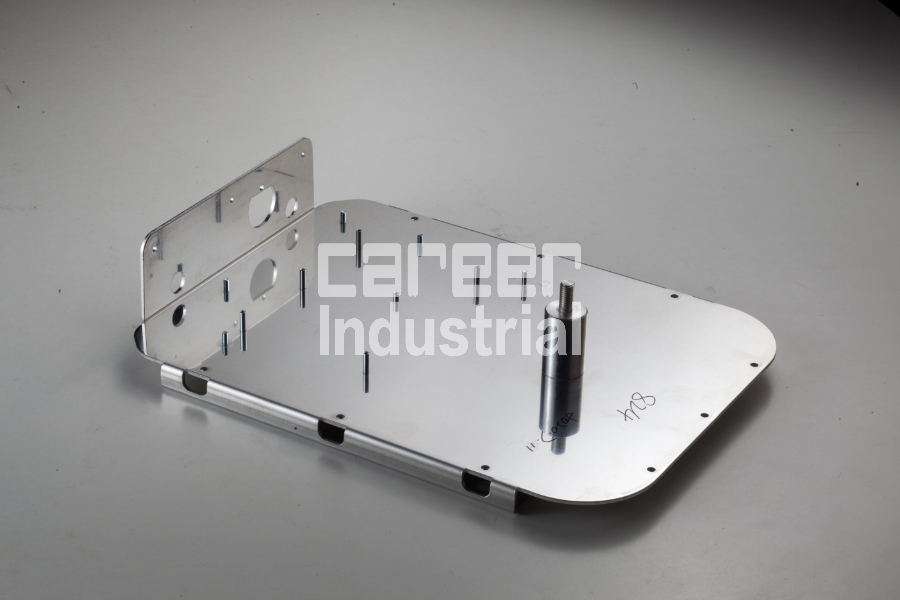

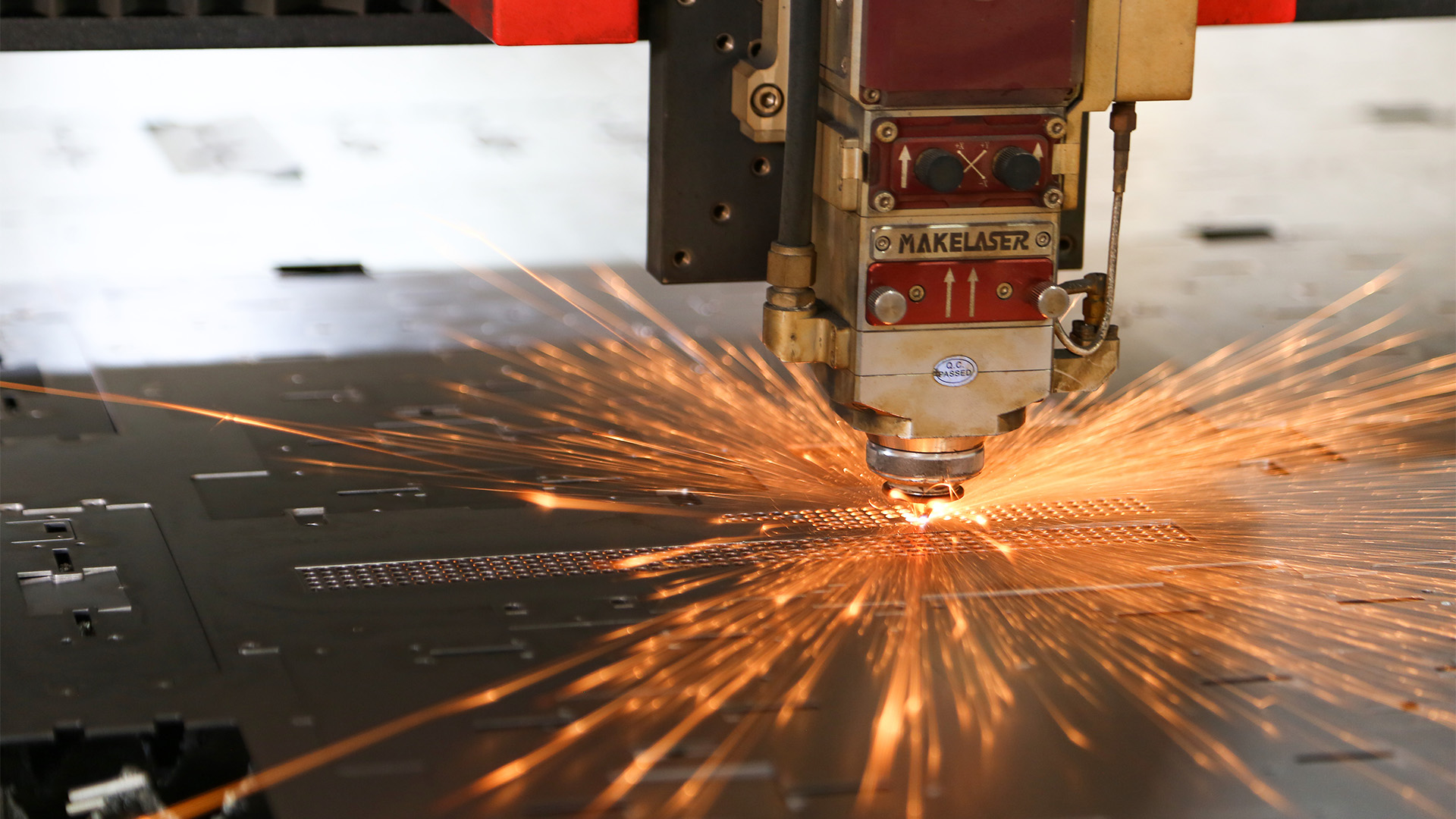

Laser cutting

Laser cutting not only save the cost of mold for customers, but also ensure the accuracy and save the time of mold production .It can finsih samples to achieve rapid delivery to global customers in 1-2 working days

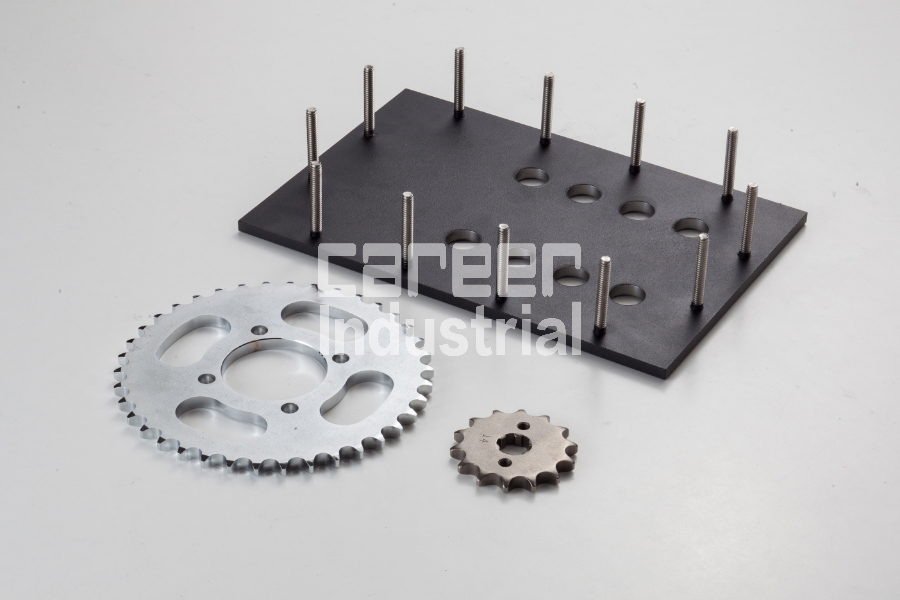

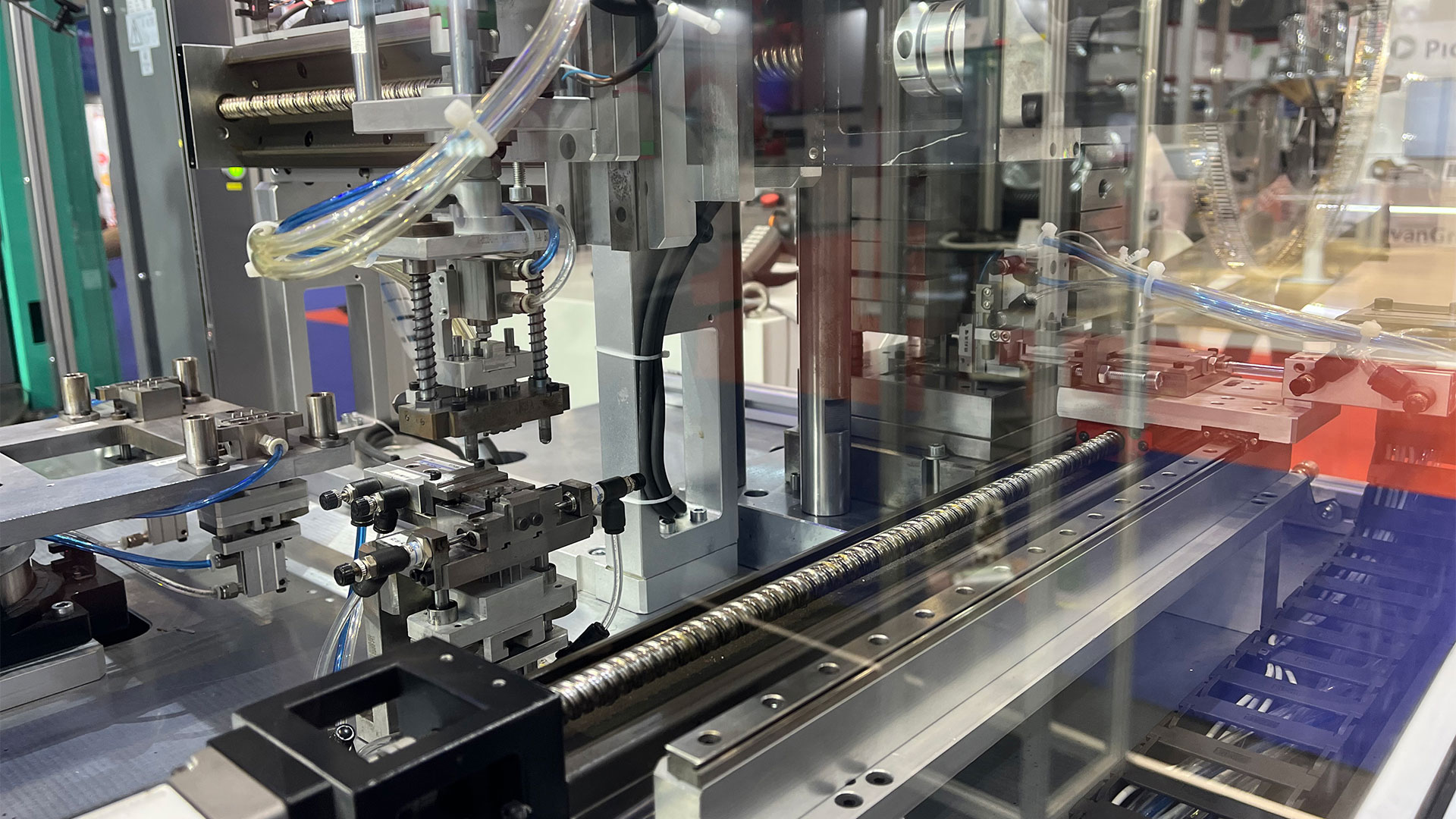

Precision complex assembly

We have nearly 10 senior engineers to provide sophisticated assembly engineering for large medical equipment, precision machinery, semiconductor packaging equipment.